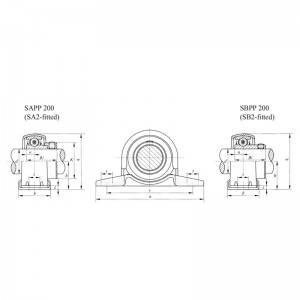

Precision sisipan bearing SAPP200 SBPP200

Bubuka

Nangtung stamping bearing titincakan, nu diwangun ku pelat baja stamping cangkang luhur jeung handap, boga kaunggulan beurat hampang jeung volume leutik dibandingkeun kalawan titincakan nangtung beusi tuang, sarta mangrupakeun tipe kalawan spasi instalasi pangleutikna dina titincakan nangtung.Tapi ngan bisa dipaké dina beban leutik.

Ciri

1. Alus anticorrosion performance.Roller awak jeung anjing laut dijieunna tina bahan polimér tinggi, korosi resistant.When dipaké di lingkungan corrosive, hirup jasa bisa ngahontal leuwih ti 5 kali tina roller biasa.

2, ngagem lalawanan, hirup layanan panjang.Bahan polimér anu luhur pikeun awak roller idler, sipat mékanisna sami sareng parunggu, gaduh résistansi ngagem anu saé, sareng gaduh sipat pelumasan diri anu saé, sareng henteu ngaganggu sabuk.

3. Struktur lumrah jeung sealing dipercaya.Idler disayogikeun ku dua segel, precision tinggi dina manufaktur, sareng gajih khusus diterapkeun dina sela, anu sacara efektif tiasa nyegah média korosif sapertos lebu, gas sareng cairan tina asup ka idler sareng ngarusak bantalan.

4. beurat lampu sarta inersia rotational leutik.Beurat bahan polimér husus pikeun idlers téh hampang, sarta beurat husus na hiji katujuh tina baja.Beurat idlers dijieunna tina bahan ieu ngeunaan hiji satengah ti idlers biasa, kalawan inersia rotational leutik sarta gesekan leutik antara idlers na belts.

Aplikasi

SAPP SBPP widang lumaku: beban lampu mesin speed low, conveyor lampu, jsb

Parameter

| Unit Bearing | Aci Dia. | Diménsi (in.) atanapi (mm) | Bolt Dipaké (in.) | SPAFL | SBPFL | Padumukan | |||||||||||||||||||||||||||

| d | |||||||||||||||||||||||||||||||||

| NO. | (di.) | (mm) | h | a | c | b | s | g (mm) | w | n | (mm) | Bi | K | Bearing No. | beurat (kg) | Bi | Bearing No. | beurat (kg) | NO. | ||||||||||||||

| SAPP SBPP | 201 | 12 | 7/8 | 3 | 3/8 | 2 | 43/64 | 63/64 | 3/8 | 1 | 23/32 | 0.2362 | 5/16 | 1.1220 | 1.1260 | SA | 201 | 0,8661 | SB | 201 | |||||||||||||

| 201-8 | 1/2 | 22.2 | 86 | 68 | 25 | 9.5 | 3.0 | 43.8 | 6.0 | M8 | 28.6 | 28.6 | 201-8 | 0.19 | 22 | 201-8 | 0.16 | PP | 201 | ||||||||||||||

| SAPP SBPP | 202 | 15 | 7/8 | 3 | 3/8 | 2 | 43/64 | 63/64 | 3/8 | 1 | 23/32 | 0.2362 | 5/16 | 1.1220 | 1.1260 | SA | 202 | 0,8661 | SB | 202 | |||||||||||||

| 202-10 | 5/8 | 22.2 | 86 | 68 | 25 | 9.5 | 3.0 | 43.8 | 6.0 | M8 | 28.6 | 28.6 | 202-10 | 0.19 | 22 | 202-10 | 0.16 | PP | 202 | ||||||||||||||

| SAPP SBPP | 203 | 17 | 7/8 | 3 | 3/8 | 2 | 43/64 | 63/64 | 3/8 | 1 | 23/32 | 0.2362 | 5/16 | 1.1220 | 1.1260 | SA | 203 | 0,8661 | SB | 203 | |||||||||||||

| 203-11 | 11/16 | 22.2 | 86 | 68 | 25 | 9.5 | 3.0 | 43.8 | 6.0 | M8 | 28.6 | 28.6 | 203-11 | 0.19 | 22 | 203-10 | 0.16 | PP | 203 | ||||||||||||||

| SAPP SBPP | 204-12 | 3/4 | 1 | 3 | 27/32 | 2 | 63/64 | 1 | 1/4 | 3/8 | 1 | 63/64 | 0,2756 | 5/16 | 1.2205 | 1.311 | SA | 204-12 | 0.9843 | SB | 204-12 | ||||||||||||

| SBPP | 204 | 20 | 25.4 | 98 | 76 | 32 | 9.5 | 3.0 | 50.5 | 7.0 | M8 | 31 | 33.3 | 204 | 0.23 | 25 | 204 | 0.23 | PP | 204 | |||||||||||||

| SAPP SBPP | 205-14 | 7/8 | 1 | 1/8 | 4 | 1/4 | 3 | 25/64 | 1 | 1/4 | 29/64 | 2 | 15/64 | 0.2953 | 3/8 | 1.2205 | 1.5 | SA | 205-14 | 1.0630 | SB | 205-14 | |||||||||||

| SAPP SBPP | 205 | 25 | 28.6 | 108 | 86 | 32 | 11.5 | 4.0 | 56.6 | 7.5 | M10 | 31 | 38.1 | 205 | 0.32 | 27 | 205 | 0.28 | PP | 205 | |||||||||||||

| 205-16 | 1 | 205-16 | 205-16 | ||||||||||||||||||||||||||||||

| SAPP SBPP | 206-18 | 1 | 1/8 | SA | 206-18 | SB | 206-18 | ||||||||||||||||||||||||||

| 206 | 30 | 1 | 5/16 | 4 | 19/32 | 3 | 47/64 | 1 | 1/2 | 29/64 | 2 | 39/64 | 0.3150 | 3/8 | 1.4055 | 1.7250 | 206 | 1.1811 | 206 | ||||||||||||||

| 206-19 | 1 | 3/16 | 33.3 | 117 | 95 | 38 | 11.5 | 4.0 | 66.3 | 8.0 | M10 | 35.7 | 44.5 | 206-19 | 0.50 | 30 | 206-19 | 0.47 | PP | 206 | |||||||||||||

| 206-20 | 1 | 1/4 | 206-20 | 206-20 | |||||||||||||||||||||||||||||